Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

On April 25th, the European Union unveiled a bold plan to phase out internal‑combustion vehicles by 2035, sparking a global media frenzy and sending electric cars up the sales charts faster than ever before. Passengers in Paris gleamed under the night lights; street‑carpenter workshops in Bangalore pivoted to supply battery plates; and automakers scrambled to expand production lines. The headline-grabbing “Zero‑Carbon Car” initiative is, at its heart, a shift to reliable electric powertrains—technology that relies, on a smaller but critical scale, on precision gear motors. Though often hidden inside the engine bay, these compact devices are the backbone of the new mobility wave.

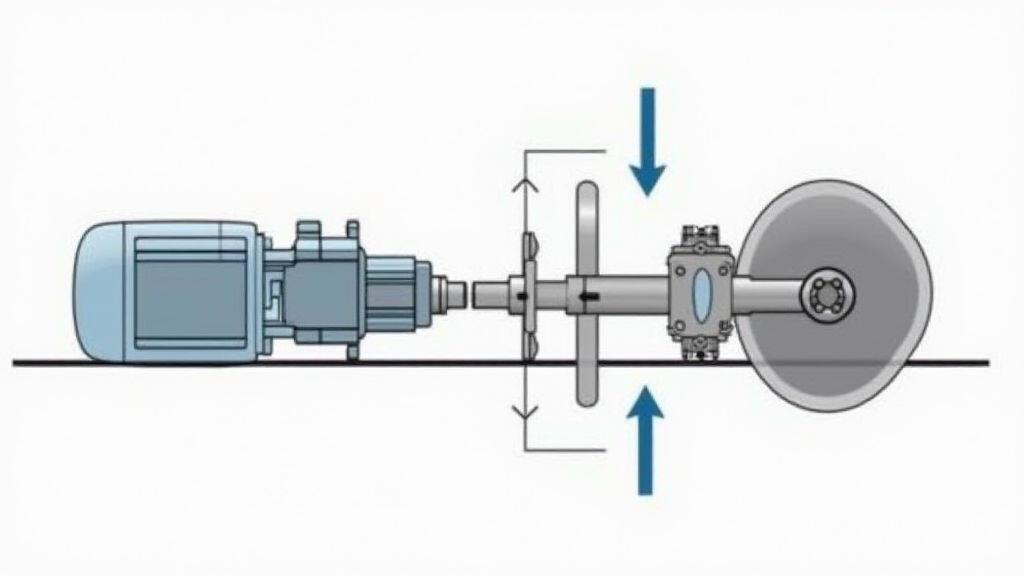

From industrial giants to household appliances, gear motors—often called reducer motors—arrange rotational speed and torque to suit the task at hand. In an electric vehicle, the rider’s torque is generated at high RPMs by a brushless DC motor; the gear motor steps that power down to usable wheels while boosting torque for acceleration and hill climbs. This simple yet essential “reduction” step is why they’re also called reducer motors.

In an EV’s drive train, the gear motor couples the high‑speed motor shaft to the low‑speed wheels, delivering an optimal balance: vehicular speed of 60–120 km/h while maintaining the motor’s peak efficiency at ~10,000–15,000 RPM. Without the gear motor, the motor would either run too slowly—wasting battery charge—or too fast, compromising wheel speed and safety.

What does the trend toward EVs mean for the gear motor market? According to the International Energy Agency, worldwide EV sales climbed 43 % in 2023, and year‑on‑year growth is projected to exceed 30 % annually through 2030. This surge translates to an estimated 1.2‑million new cars entering the market, many of which will use gear motors in their powertrains. Beyond the front‑wheel‑drive architecture, manufacturers are also exploring steering and braking functions that rely on gear motors for redundancy and precise torque control—pushing the component’s demand even higher.

While the raw numbers are impressive, the quality expectations are equally demanding. EV gear motors must meet three critical criteria:

Given these demands, many automakers are partnering with specialized gear motor manufacturers. For instance, Tesla’s Model 3 powertrain incorporates a 10.5:1 planetary gear motor that couples a 250 kW motor to the chassis. Benchmark experiments conducted by the National Institute of Standards and Technology show a 4 % fuel‑equivalent savings when using the latest generation of gear motors—an attractive selling point in markets where fuel‑car ratings still influence buyer decisions.

Beyond the car itself, the rising popularity of e‑mobility for delivery vans, light electric trucks, and shared mobility services is opening new avenues. Delivery fleets in cities such as New York and Shanghai are adopting electric vans that rely on gear motors to balance high torque demands at city speeds with the need for lightweight, efficient components. The declining cost of these motors is helping fleet owners justify the upfront investment—now the gear motor is less a cost burden and more a direct contributor to lower operating expenses.

Looking ahead, what will gear motors look like in the next decade? First, the integration of AI-driven diagnostics will allow the motor’s control system to predict and preempt wear, extending life by up to 15 % in service. Second, with the increasing focus on miniaturization, 3D‑printed gear trains using carbon‑fiber reinforced thermoplastics might reduce weight by a third while maintaining strength—an essential advancement for high‑speed EVs that aim to compete with traditional sports cars. Third, sustainability will remain top priority: fully recyclable gear motor systems, combined with regenerative braking, could turn a motor's own heat into usable battery charge, creating a closed‑loop efficiency cycle.

In a world where the buzz is “clean energy, zero emissions, full autonomy,” the humble gear motor is quietly ensuring that electric vehicles not only reach the destination but do so safely, efficiently, and sustainably. Whenever a new electric car rolls onto the roads, the gear motor is that indispensable, unseen partner—reducing high‑speed rotations into precise, usable motion.

As governments push for greener transportation and consumers demand lower operating costs, the gear motor’s role is poised to expand beyond traditional cars to trucks, drones, and even autonomous robots. The next wave of technological breakthrough may come from rethinking the very core of gear design itself, and it will be the gear motor that keeps the entire electric fleet ticking on the road to zero‑carbon mobility.

Leave A Reply

Your email address will not be published. Required fiels are marked